| Product Attribute | Attribute Value |

|---|---|

| Application | Control Systems |

| Communication Port Type | USB 2.0, HDMI Type A |

| For Use With | groov EPIC® System |

| Mounting Type | DIN Rail |

| Series | |

| Special Features | Lifetime Warranty |

| Standards | UL/cUL (Class 1 Div. 2), CE, ATEX (Category 3, Zone 2), RoHS, DFARS |

| Warranty | 30 months |

Overview

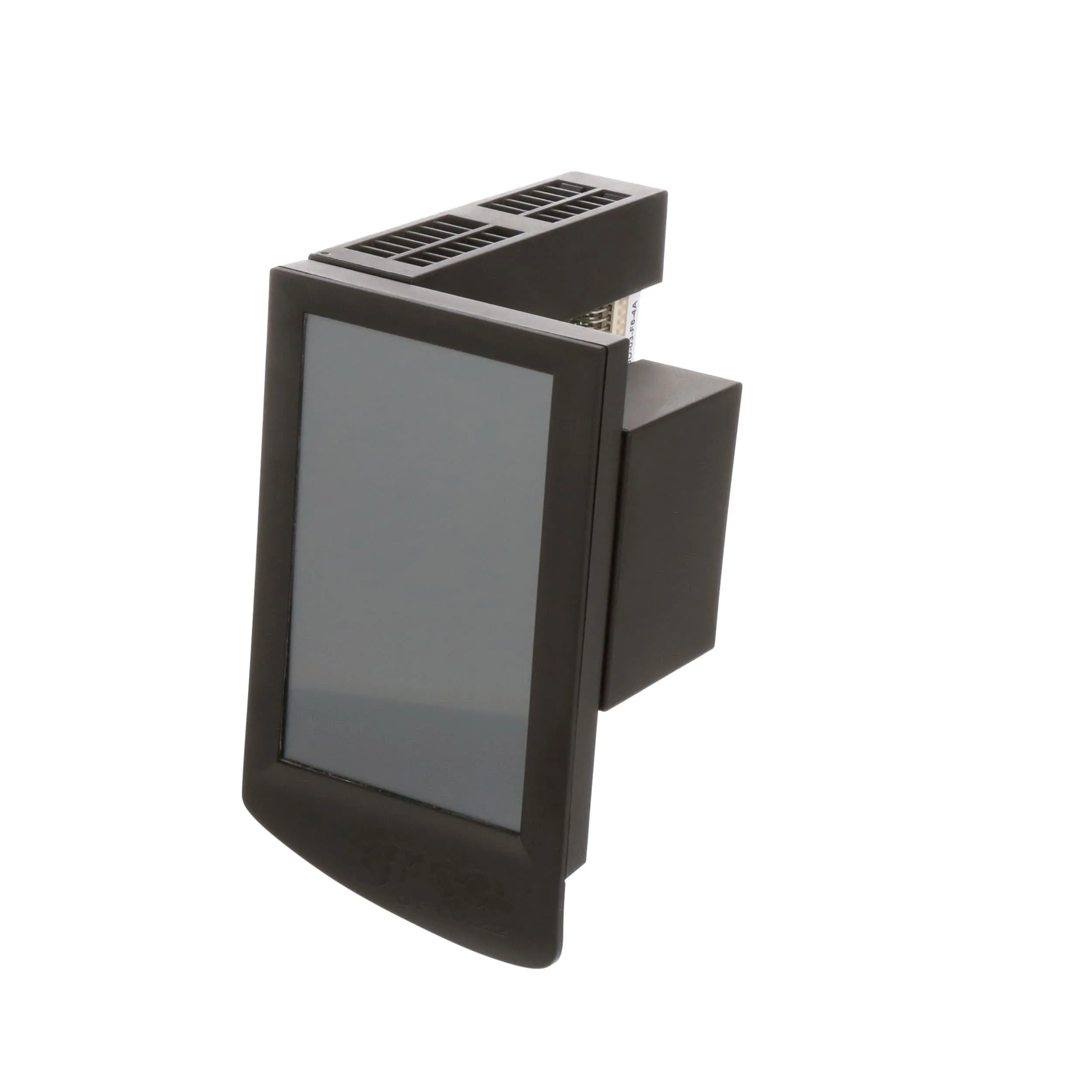

Opto22 groov EPIC Series — GRV-EPIC-PR1 | EPIC PR1 Processor:

The Edge Programmable Industrial Controller is an embedded Linux®, real-time controller with gateway functions. The modern design of the groov EPIC processor offers a condensed and sturdy unit that features a resistive-touch, high-resolution LCD display. The LCD display lifts to provide easy access to the power button, power supply connectors, network interfaces, ports, and status LEDs. The processor can operate through a wide range of operating temperatures (-20 to 70 °C) and with its sturdy design, it can be used in a large variety of applications and operating environments. It runs on an industrial, quad-core ARM® processor with a real-time, opensource Linux operating system.

The groov Manage app gives you central command-like access to your groov EPIC system, helping you configure, troubleshoot, and commission your system. The consistency in interface design between the groov Manage app running on the groov EPIC processor and the groov Manage app running on your computer, smartphone, or tablet ensures a seamless experience between devices. You don’t have to remember to do something different for each device to achieve the same result.

Features:

Software included: groov Manage, PAC Project Basic, groov View, Node-RED, Ignition Edge®

— Commission your system with web-based groov Manage, viewable by authorized users from the integrated touchscreen or from a computer or mobile device.

— Program your EPIC using flowchart-based PAC Control with optional scripting. Or build your own custom program with secure shell access (SSH). Future support planned for IEC 61131.

— Easily build the HMI you need for all your systems, devices, and data using groov View. Then securely use your HMI locally on the EPIC's high-resolution touchscreen and from anywhere on any authorized computer or mobile device. You can also build a traditional Microsoft® Windows®-based HMI using PAC Display.

— Create simple logic flows with Node-RED. Use pre-built nodes to exchange data with equipment, online services, and more.

— Connect to Allen-Bradley® and Siemens® PLCs with the included OPC-UA drivers from Ignition Edge (a product of Inductive Automation®) (requires a groov Enterprise license).

— Efficiently exchange data for IIoT projects using MQTT communications with Sparkplug payload, also provided by Ignition Edge Onboard (requires a groov Enterprise license).